Z-Scores questions examples

Question 1: Z-Score Calculation for Process Improvement

A manufacturing process for producing electronic components has a mean output of 100 units per hour with a standard deviation of 10 units. The upper specification limit (USL) for acceptable production is 120 units per hour. Calculate the Z-score for the USL and interpret its significance for process improvement.

Solution:

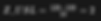

To calculate the Z-score for the USL, use the formula:

Substituting the given values:

Interpretation: A Z-score of 2 indicates that the upper specification limit is 2 standard deviations away from the mean production rate. This suggests that the probability of producing more than 120 units per hour is low, but there's room for improvement to increase process capability and further reduce the risk of exceeding the USL.

Question 2: Comparing Process Performance Using Z-Scores

Two assembly lines produce the same product. Line A has a mean defect rate of 2 defects per 100 units with a standard deviation of 0.5, and Line B has a mean defect rate of 1.5 defects per 100 units with a standard deviation of 0.4. If the upper specification limit for defects is 3 per 100 units, which line has better process performance in terms of Z-score?

Solution:

Calculate the Z-score for both lines:

For Line A:

For Line B:

Interpretation: Line B has a higher Z-score (3.75) compared to Line A (2), indicating that Line B is performing better relative to the upper specification limit. This means Line B has a lower probability of producing defects beyond the specification limit compared to Line A.

Question 3: Process Centering and Z-Score Improvement

A process has a lower specification limit (LSL) of 50 units and an upper specification limit (USL) of 70 units. The process currently operates with a mean of 60 units and a standard deviation of 4 units. The process owner wants to improve the Z-score for the LSL by re-centering the process without changing the standard deviation. To what new mean should the process be centered to achieve a Z-score of 3 for the LSL?

Solution:

To find the new mean (3.75μnew) that achieves a Z-score of 3 for the LSL, use the formula for the Z-score:

Rearranging the formula to solve for μnew:

Substituting the given values:

Interpretation: To achieve a Z-score of 3 for the LSL, the process should be re-centered to a new mean of 62 units. This adjustment will increase the process's capability by reducing the likelihood of producing units below the LSL, without changing the process variability.

These questions and solutions illustrate the application of Z-scores in evaluating and improving process performance, key concepts in Lean Six Sigma methodologies.

Question 4: Evaluating Process Shift with Z-Scores

A process producing chemical compounds has been evaluated for its purity levels. The target purity level is set at 95%, with a standard deviation of 2%. Historical data shows that the process mean purity level was at 94%. However, after implementing a quality improvement initiative, the new process mean purity level increased to 96%. Calculate the Z-score for the target purity level before and after the improvement initiative. What does the change in Z-score indicate about the process improvement?

Solution:

Calculate the Z-score for the target purity level before and after the process improvement:

Before Improvement:

After Improvement:

Interpretation: The Z-score before the improvement was 0.5, indicating that the process mean was half a standard deviation below the target. After the improvement, the Z-score is -0.5, indicating the process mean is now half a standard deviation above the target. The change in Z-score reflects a positive shift in the process mean towards higher purity levels, demonstrating the effectiveness of the quality improvement initiative. The negative sign of the Z-score after improvement simply indicates that the mean is above the target, which, in this context, is a favorable outcome.

Question 5: Impact of Standard Deviation Reduction on Z-Score

A call center aims to reduce the average handling time (AHT) of calls to within a specific target range. The lower specification limit (LSL) for AHT is set at 180 seconds, and the upper specification limit (USL) is 300 seconds. Initially, the process has a mean AHT of 240 seconds and a standard deviation of 30 seconds. Management implements a training program that reduces the standard deviation to 20 seconds without altering the mean. Calculate the initial and new Z-scores for both the USL and LSL, and assess the impact of the training program on process capability.

Solution:

Calculate the initial and new Z-scores for both the USL and LSL:

Initial Z-scores:

New Z-scores after reducing standard deviation:

Interpretation:

The initial Z-scores for both the USL and LSL were 2, indicating that the mean AHT was two standard deviations away from both specification limits. After the training program, which reduced the standard deviation to 20 seconds, the Z-scores increased to 3 for both limits. This increase in Z-scores signifies an improvement in process capability, as the process variability decreased, making the process more capable of meeting the specification limits. The training program effectively enhanced the call center's performance by reducing variability in call handling times.