Z-Test (for large sample sizes)

In the realm of Lean Six Sigma, hypothesis testing stands as a cornerstone methodology for making decisions based on data. Among the array of hypothesis tests, the Z-test is particularly significant when dealing with large sample sizes. This article aims to demystify the Z-test, outlining its purpose, application, and how it integrates into the Lean Six Sigma framework.

What is a Z-Test?

A Z-test is a type of hypothesis testing used to determine whether two population means are different when the variances are known and the sample size is large (typically, n > 30). The Z-test utilizes the Z-statistic, which follows the standard normal distribution under the null hypothesis, to measure the difference between the sample mean and the population mean relative to the standard deviation of the population.

Key Components of the Z-Test

Population Mean (μ): The average value of a population.

Sample Mean (xˉ): The average value of a sample drawn from the population.

Population Standard Deviation (σ): A measure of the dispersion of the population. In the Z-test, it's assumed to be known.

Sample Size (n): The number of observations in the sample. For the Z-test, a larger sample size validates the normal approximation of the sampling distribution.

Z-Statistic: A measure that calculates the number of standard deviations the sample mean is from the population mean.

When to Use a Z-Test

The Z-test is most appropriate under the following conditions:

The sample size is large (n > 30), which, according to the Central Limit Theorem, ensures the sampling distribution of the sample mean approximates a normal distribution.

The population standard deviation (σ) is known, allowing for precise calculation of the Z-statistic.

The data points are independent of each other.

The Process of Conducting a Z-Test

State the Hypotheses:

Null Hypothesis (H0): There is no difference between the population mean and the sample mean (0μ=μ0).

Alternative Hypothesis (Ha): There is a significant difference (μ≠μ0).

Select the Significance Level (α):

Common values are 0.05 or 0.01, representing a 5% or 1% risk of concluding a difference when there is none.

Calculate the Z-Statistic:

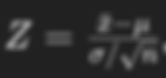

Use the formula:

where xˉ is the sample mean, μ is the population mean, σ is the population standard deviation, and n is the sample size.

4. Determine the Critical Value or P-value:

Compare the calculated Z-statistic against the critical values from the Z-table or calculate the P-value.

5. Make a Decision:

If the Z-statistic is beyond the critical value or the P-value is less than α, reject the null hypothesis in favor of the alternative. Otherwise, do not reject the null hypothesis.

Application in Lean Six Sigma

In Lean Six Sigma projects, the Z-test plays a vital role in the Analyze phase of the DMAIC (Define, Measure, Analyze, Improve, Control) methodology. It helps to validate or refute assumptions about process improvements or changes. For instance, if a process change is hypothesized to increase the output mean, a Z-test can statistically confirm if the change made a significant difference.

Conclusion

The Z-test is a powerful statistical tool in Lean Six Sigma for hypothesis testing with large sample sizes. By understanding when and how to apply the Z-test, practitioners can make informed decisions backed by statistical evidence, leading to more effective and efficient process improvements.

Real-Life Based Scenario: Improving Delivery Times

Hypothesis testing is a statistical method used in Lean Six Sigma to make decisions using data. The Z-test, specifically, is used to determine whether there is a significant difference between the mean of a sample and the known mean of a population, particularly when the sample size is large (n > 30) and the population standard deviation is known.

A courier company aims to improve its delivery times. The company has a standard delivery time of 48 hours for a specific type of parcel delivery. To assess the effectiveness of a new delivery process, the company decides to conduct a hypothesis test using a sample of 50 deliveries.

Objective: Determine if the new delivery process significantly improves delivery times compared to the standard 48-hour delivery time.

Step 1: Define Hypotheses

Null Hypothesis (H0): The mean delivery time of parcels using the new process is equal to 48 hours.

Alternative Hypothesis (H1): The mean delivery time of parcels using the new process is less than 48 hours.

Step 2: Collect Data

The company collects a random sample of 50 deliveries using the new process. The sample has an average delivery time of 46.5 hours with a standard deviation of 5 hours.

Step 3: Choose the Significance Level

The company decides on a significance level (α) of 0.05, which is a commonly used threshold indicating a 5% risk of concluding that a difference exists when there is none.

Step 4: Calculate the Z-Test Statistic

The Z-test statistic is calculated using the formula:

Where:

Xˉ = sample mean = 46.5 hours

μ = population mean = 48 hours

σ = population standard deviation = 5 hours

n = sample size = 50

Step 5: Determine the Critical Z-Value

From the Z-table, for a significance level of 0.05 (one-tailed test), the critical Z-value is -1.645.

Step 6: Make the Decision

Since the calculated Z-value of -2.12 is less than the critical Z-value of -1.645, we reject the null hypothesis.

Step 7: Interpret the Results

By rejecting the null hypothesis, the company concludes that the new delivery process significantly reduces the delivery times compared to the standard 48-hour delivery time at the 5% significance level. This indicates that the improvements made in the delivery process are effective.

Conclusion

Using the Z-test, the courier company has statistically validated that the new delivery process improves delivery times. This example demonstrates how Lean Six Sigma practitioners can use hypothesis testing to make data-driven decisions to enhance operational processes.

Video

Great video for your Z-test understanding:

Great video for your Z-test understanding, because this is a typical question in the Black Belt exam.